It's not a problem for us

Design and Development

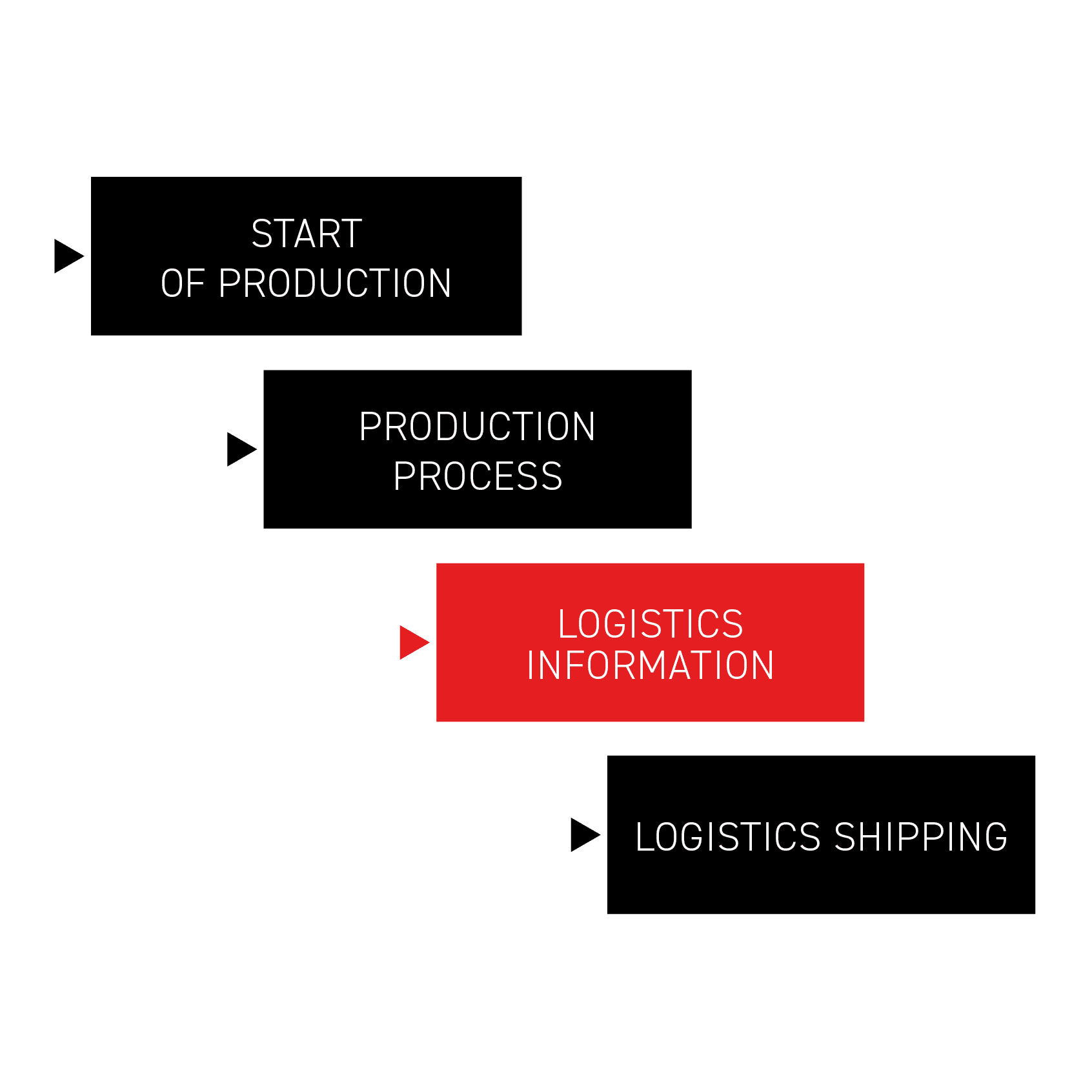

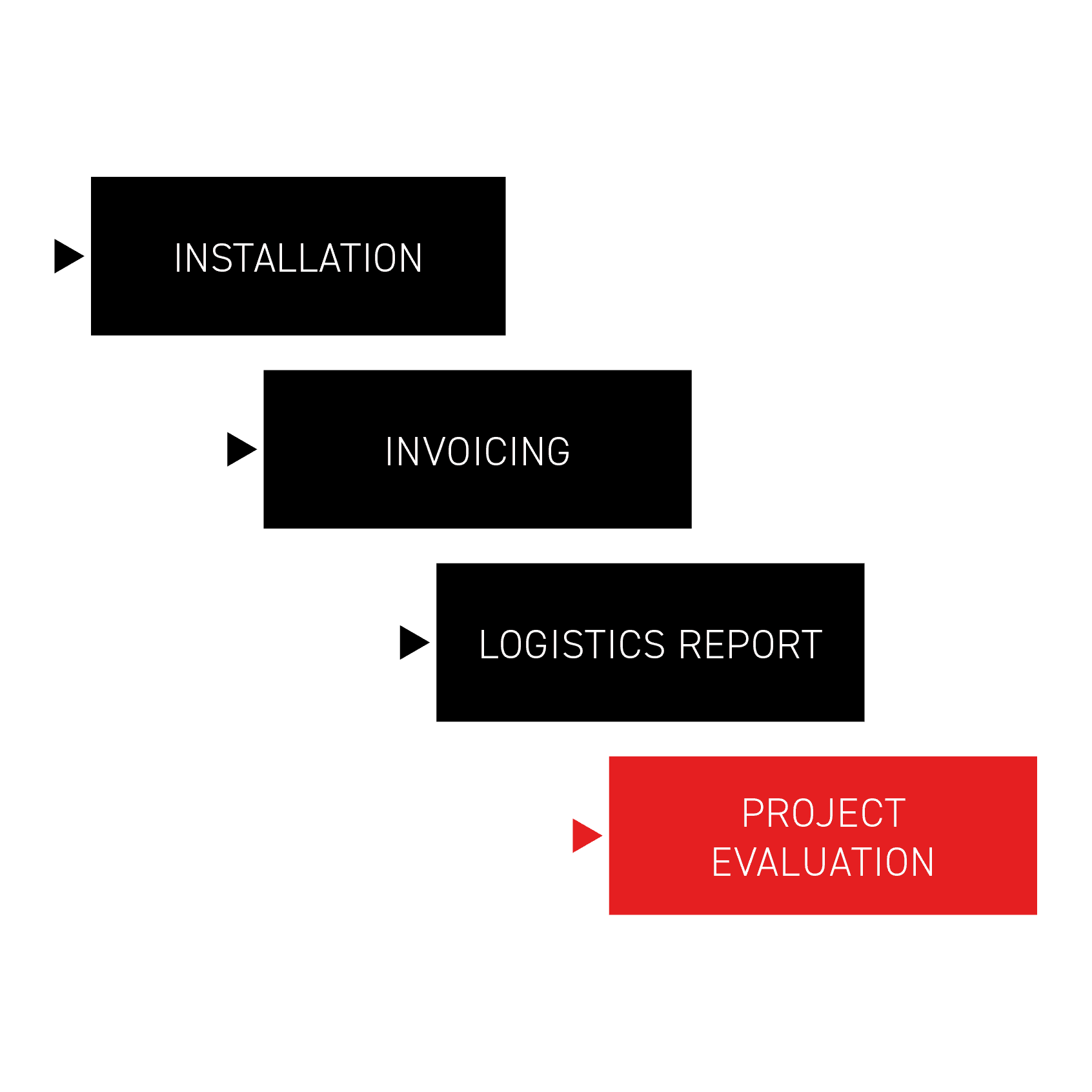

What's the hardest thing about design? The idea itself! In our hands we create innovative POS and interior decoration designs. Thanks to our many years of experience, we have turn-key designing down to a science. Our extensive graphics department produces 2D and 3D graphics and their functionality can be seen immediately in practice thanks to the availability of all technologies under one roof. See how the whole process works.

Creation of design

Sketches and drawings

The initial meeting, meeting the product and the client's idea is the starting impulse for the whole process of project realization, therefore it is necessary to formulate the assignment as precisely as possible. Only in this way will we be able to meet your expectations. Designing a suitable solution often starts in the form of simple hand-drawn sketches or the creation of a 3D material study for a project. Our designers have detailed knowledge of materials and technologies, plus they work closely with experienced production colleagues. As a result, we are usually able to offer you multiple possible solutions, both in terms of design and materials.

DTP, 2D and 3D graphics

Using 3D graphics, our design team will produce a realistic visualisation of your project, optimally set in a real environment. At this stage, we can therefore have an idea of what the project will look like and, thanks to 3D, we know its exact proportions. Thanks to this, we are able to create realistic parts of the stands for the deployment of the final graphics together with the production of the print data.

3D printing

If you want a unique decoration or any other product that is suitable for production on our fleet of 3D printers, the process will be similar. You will provide us with ideas about the final form of the print, what features it should have, number of pieces, colors, etc. Our 3D graphics department will make a 3D model for which we will make a test 3D print, which we will approve, or process the client's comments. After approval of the final sample, the product can go into mass production, or we can process the decoration in a few pieces.

Development of the stand design

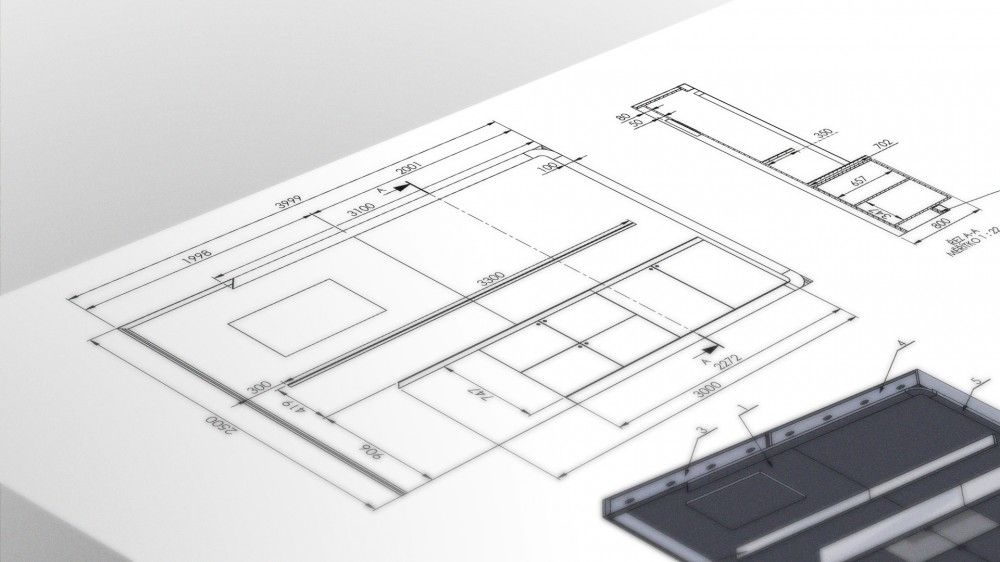

Technical documentation

Based on the agreed visuals, the next stage is the technical development of the product. Experienced production engineers choose the appropriate materials, processing and create detailed technical documentation in the form of drawings. This phase is very time-consuming, each sub-element must be very carefully documented for the actual production and also serves as a basis for the price calculation. Of course there are also instructions for assembling or assembling the stands, etc.

Making the prototype

In order to make sure that the target product will have the necessary quality and fulfil its function, we make so-called prototype tests. These are then subjected to long-term weight and transport tests. Often, the stands go to the stores already filled with goods and undergo additional handling and transport loads. With the approval of the prototype, we can start mass production.